Describe 5 Tools Being Used in Sand Casting

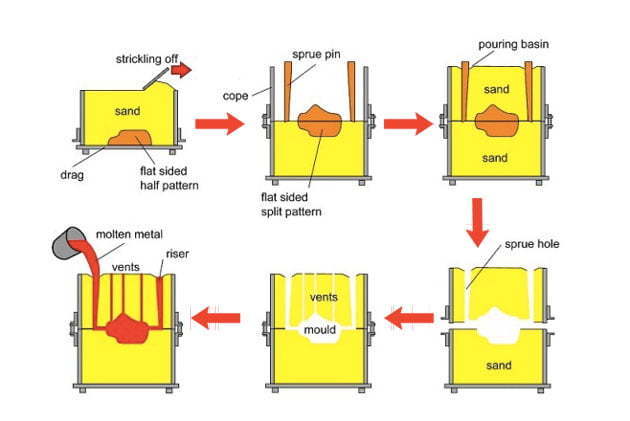

Green sand refers to the sand molds formed from wet sand and is sometimes referred to as clay. Here is a step-by-step procedure of the sand casting process.

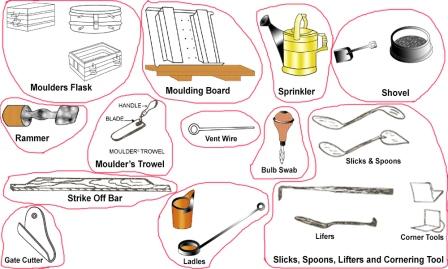

10 Foundry Tools And Equipments That You Should Know

There are many processes and tools that are involved in casting the sand.

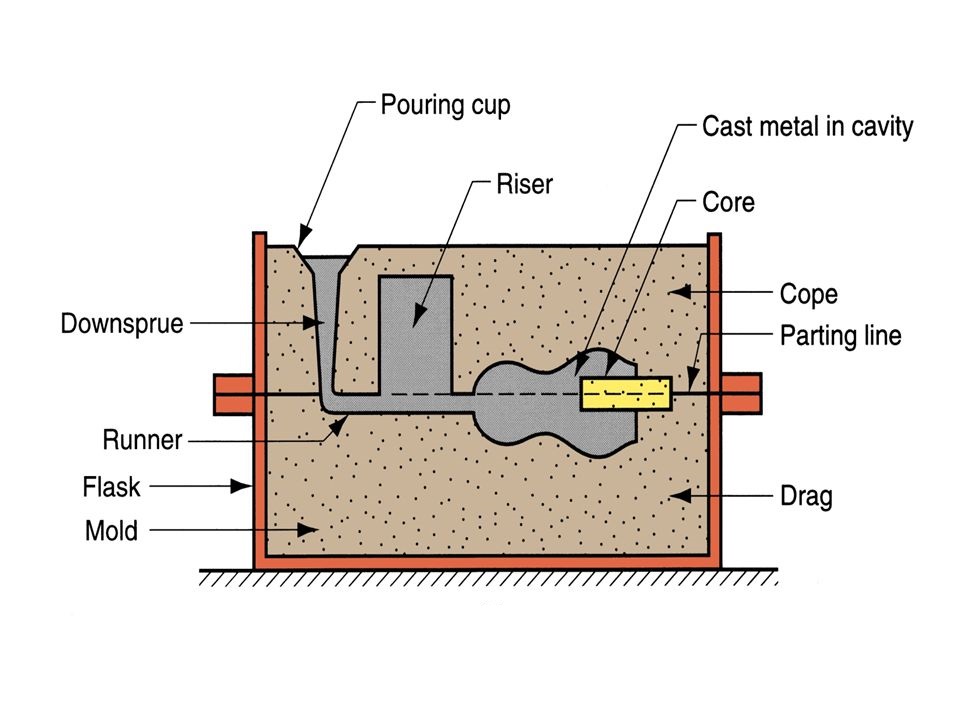

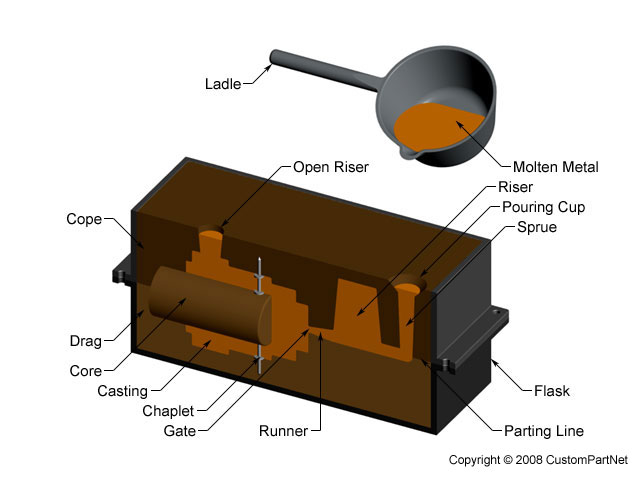

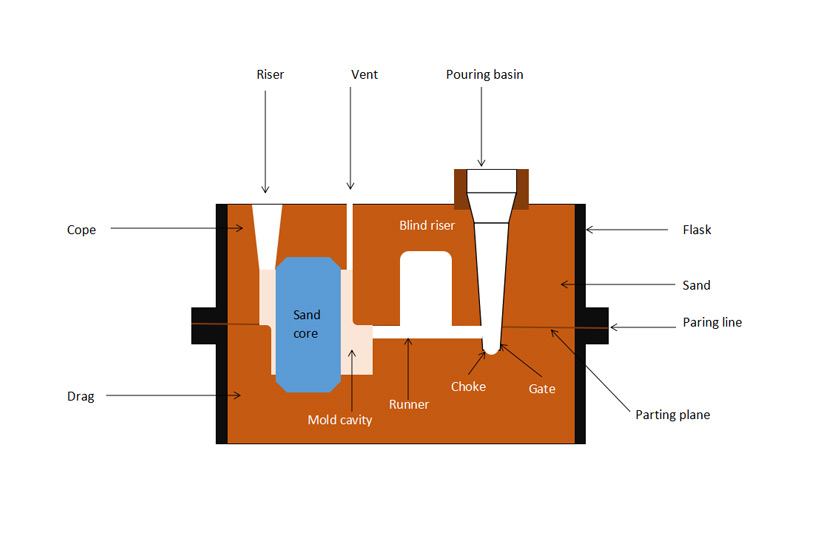

. ② The most used clay wet sand can be recycled after proper sand treatment. The sand mold separates along a. The molten metal solidifies in the cavity between the interior of the mold and the exterior of the core.

A machine used to mix sand for casting. Sand castings are produced in specialized factories called foundries. Mixture is placed in a core box and squeezed against the pattern to form a mold.

Different types of Casting tools and equipment Hand riddle. Testing of Mould Core sand. This step involves creating a replica or duplicate of the object that will be cast.

The sand casting process involves the use of a furnace metal pattern and sand mold. 3 Core hardness test. Sodium silicate can also be used to create the mold casting.

On one hand casting is a deceptively simple manufacturing process. The sand used is very finely grained has a clay content eg. 1 Preparation of standard test specimen.

Patternmaking The first step in sand casting is patternmaking. Anyone who has formed castles at the beach knows sand can be used to make detailed shapes. Sand bentonite clay coal and water.

The first step of sand casting involves the placement of the mold pattern in sand. Plaster casting is similar to sand casting except that plaster of paris is substituted for sand as a mold material. Vintage Pattern Maker Foundry Sand Casting Floats Spoons Antique Tool.

Sand casting is a process that utilizes non-reusable sand molds to form metal castings. 7 Permeability test. Generally the form takes less than a week to prepare after which a production rate of 110 unitshrmold is achieved with items as massive as 45 kg 99 lb and as small as 30 g 1 oz with very good surface finish and close.

Sodium Silicate can quickly. Sodium Silicate or Water Glass. 4 Moisture content test on foundry sand.

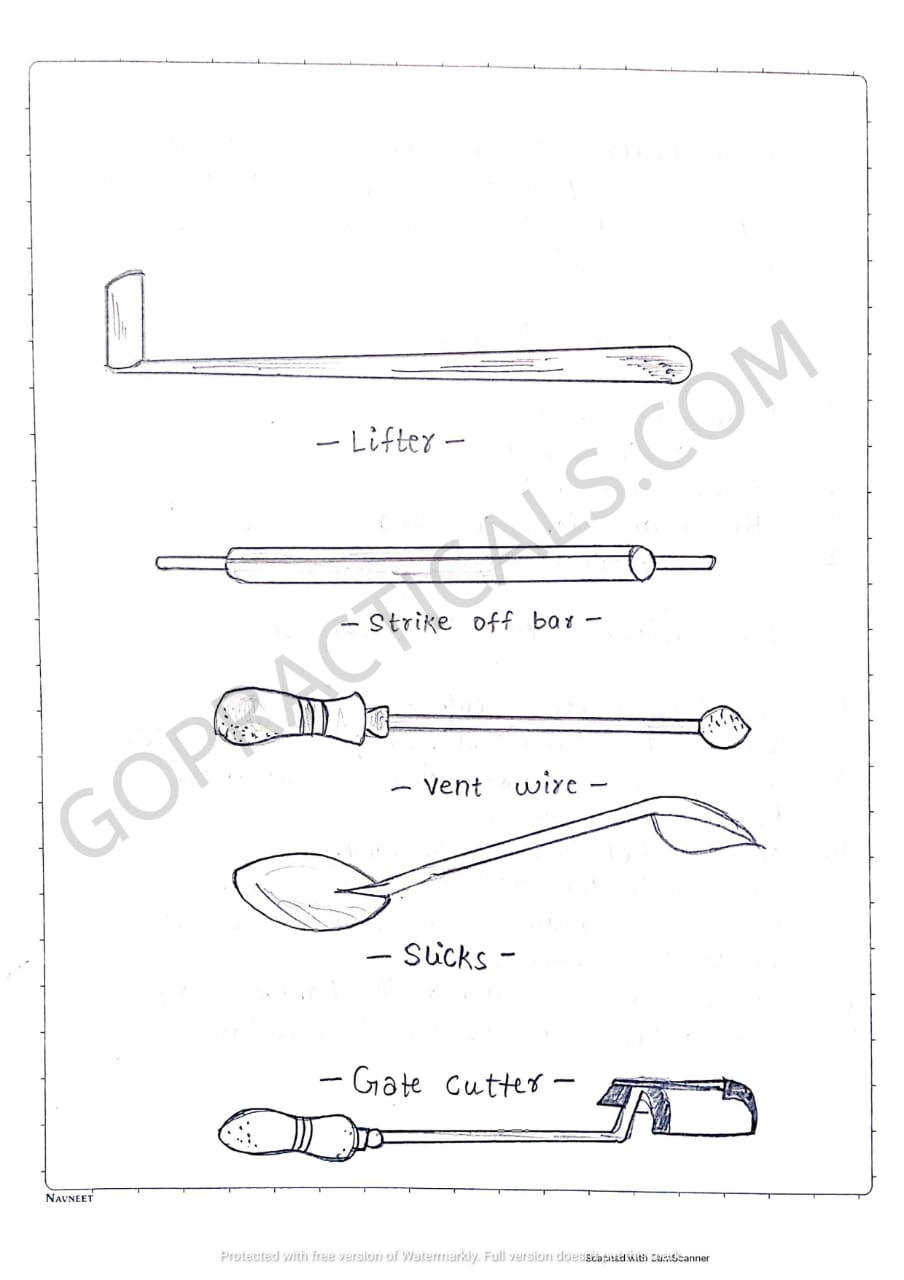

2 Mould hardness test. Cooling the mold to the room temperature. The principal casting tools are hand tools containers and mechanical tools.

Step 1 Place Mold Pattern in Sand. The type of pattern that has only one part. Pouring the molten metal in the mold cavity.

The six main steps in this process are. They are used for moving or transferring the molding sand into the container molding box or flask. ④ The mixed molding sand can be used for a long time.

Mold can be used immediately for casting. Sand casting involves several steps including patternmaking molding melting and pouring and cleaning. For very large or heavy castings mold is often bakeddried in an oven to improve mold strength and rigidity.

① Clay is rich in resources and cheap. Making a proper gating system in the mold. Therefore manufacturing companies must create new molds to create metal products and components in specific sizes and shape.

Breaking the mold and getting the casting. Green sand around a Pattern. So care should be taken while making delicate products.

Hand tools consist of the rammer shovel riddle vent wire lifter slick trowel mallet swab clamps gagger bellow etc. The metal is melted in the furnace and then ladled and poured into the cavity of the sand mold which is formed by the pattern. The pattern is the form around which the sand is packed usually in two parts the cope and the drag.

6 Clay content test. 5 Sieve analysis. The type of pattern that consists of two or more parts used to make round or irregular molds.

Which materials are commonly used for casting. After sand blasting the castings will need workers to grind them by grinding tools to remove the burrs and sharp edges. See also Cast Aluminium Plaquette for a simple practical project example.

They are used for separating sand and another object that serve as obstacles when molding. Sand Casting aka Green Sand Casting is a process in which molten metal is poured into a mould cavity made by forming damp ie. What Type of Sand is Used for Sand Casting.

Mechanical tools are generally used in automated foundries. What tools are used in casting. The term sand casting can also refer to an object produced via the sand casting process.

Sand casting also known as sand molded casting is a metal casting process characterized by using sand as the mold material. Advantages of sand casting. A ceramic or graphite container used to hold metal as it is melted.

Fill with aluminum pieces. Some examples of items manufactured in modern industry by sand casting process are cylinder heads valves engine blocks pump housings machine tool bases pulleys engine manifolds bearings gears bushings brush holders brackets lever arms electrical contact parts hardware machinery parts nuts landing gear. Sand blasting equipments are the main cleaning equipments and there are mainly hook-type crawler transfer desktop shot blasting machines.

Over 60 of all metal castings are produced via sand casting process. Tools Needed 1 Silica Sand 2 Mold of object 3 Some type of kilnoven to melt the metal you will be using 4 Ladle to pour molten metal 5 Block of solid metal to melt 6 Hammer or some other object to crack the sand mold after metal solidifies Ask. Define the cavity inside a mold.

Pattern making and placing it the sand mold. A mixture of sand and binders. ⑤ After the sand mold is compacted it can still be subjected to a small amount of.

Ending Mar 29 at 600PM PDT 3d 23h. Cast Iron 2 Part Flask Mold for Delft Sand Casting Jewelry Making Tool. They work together and sequentially until the goal of the process accomplished.

A device used to measure high temperatures. Molds made of sand are. ③ Short manufacturing cycle and high work efficiency.

Sand Casting Mold Frame Cast Iron 2-Part Flask for Jewelry Metal Casting Tool. In addition sand is used to make any cores that are contained in the mold. Bentonite of around 12 to enable it to retain sufficient.

Use a crucible made of Clay Graphite or Silicone Carbide to withstand the temperature of molten metal. There are the five basic steps to creating a sand casting. The size and shape of the casting is directly influenced by the mold.

Other Expendable Mold Casting Shell Molding Vacuum Molding Expanded Polystyrene Process. 8 Compression shear test. After the sand is compacted enough to replicate the pattern the cope is removed and the pattern extracted.

However in a foundry dealing with the heat of molten metal many factors must be considered for.

Guide To Sand Casting Premier Engineered Products

Foundry Tools And Equipment List Names Images Marinerspoint

20 Different Hand Moulding Tools For Sand Casting Or Moulding

Casting Terminology Bajrang Engineering

Sand Casting Process Defects Design

Foundry Shop Introduction Tools And Precautions Workshop Practical

10 Foundry Tools And Equipments That You Should Know

20 Different Hand Moulding Tools For Sand Casting Or Moulding

Hand Tools Used In Foundry Shop Engineers Gallery

Instructions For Making Sand Casting Molds In Detail Step By Step

Green Sand Casting How To Apply On Foundry Casting Parts Processes

Types Of Sand Casting Tools And Equipment Studentlesson

What Is Casting Core Prints Use Of Core Prints

Sand Casting Method Ganoksin Jewelry Making Community

Jewelers Sand Casting Tool Kit Complete Grobet Http Www Amazon Com Dp B000ovnkwu Ref Cm Sw R Pi Dp Zpsaub1bf53b9 Sand Casting Metal Products It Cast

Sand Casting Process Defects Design

Sand Casting An Overview Sciencedirect Topics

Comments

Post a Comment